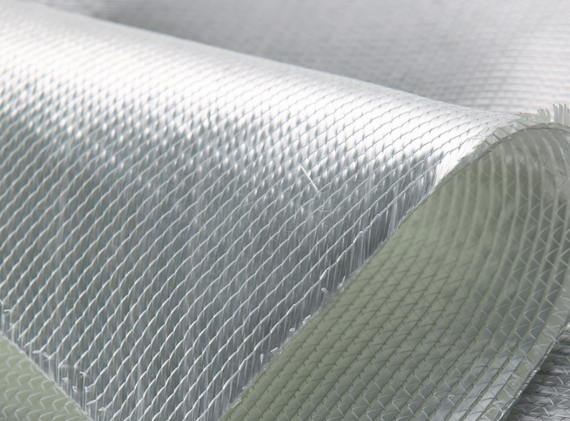

玻璃纤维三轴向织物

Fiberglass triaxial fabric

众杰玻璃纤维多轴向织物是由无碱玻璃纤维直接纱在0°/+45°/-45°或+45°/90°/-45°方向排列后以聚酯缝编线缝编而成,可选用短切原丝层加工成多轴向经编复合毡。适用于各种树脂增强系统,如不饱和聚酯树脂,乙烯基树脂和环氧树脂等。广泛应用于真空,手糊,拉挤,RTM等成型产品,如船体,风电叶片,汽车部件,运动器材,大型容器及其他玻璃钢制品。

Fiberglass triaxial fabric is made of fiberglass direct roving parallel aligned in 0°,+45°,-45°or +45°,90°,-45°directions, then stitched together with or without chopped strand layer as combo mat. It is compatible with Polyester, Vinyl and Epoxy resin and widely used in boat building, wind energy, automotive, sports equipment, containers etc, suitable Vacuum infusion, hand lay-up, pultrusion, RTM forming processes.

基本数据

General Data

规格型号 Code | 质量 Weight (g/m2) | 0°克重 (g/m2) | +45°克重(g/m2) | 90°克重(g/m2) | -45°克重(g/m2) | 短切层 Chop layer (g/m2) |

ELTX600 | 600 | 300 | 150 | - | 150 | - |

ELTX750 | 750 | 300 | 225 | - | 225 | - |

ETTX750 | 750 | - | 200 | 350 | 200 | - |

ELTX900 | 900 | 300 | 300 | - | 300 | - |

ETTX900 | 900 | - | 225 | 450 | 225 | - |

ELTX1200 | 1200 | 700 | 250 | - | 250 | - |

ELTXM1200/300 | 1500 | 700 | 250 | - | 250 | 300 |

ETTXM1200/300 | 1500 | - | 250 | 700 | 250 | 300 |

Remarks:

Roll width: Standard width in1250mm, 1270mm, and other sizes depends on customer’s real needs, available in 200mm to2600mm.

Packing: Fiberglass triaxial fabric is usually rolled in a paper tube with inner diameter 76mm. The roll is warped with plastic film, then put into carton. Lay the rolls horizontally, and can be loaded on pallets and bulk in container.

Storage: The product should be stored in a cool, water-proof area. It is recommended that the room temperature and humidity be always maintained at 15℃ to 35℃ and 35% to 65% respectively. Please keep the product in its original packaging before being used, avoiding moisture absorption.

苏公网安备32041102001451号

苏公网安备32041102001451号

苏公网安备32041102001515号

苏公网安备32041102001515号