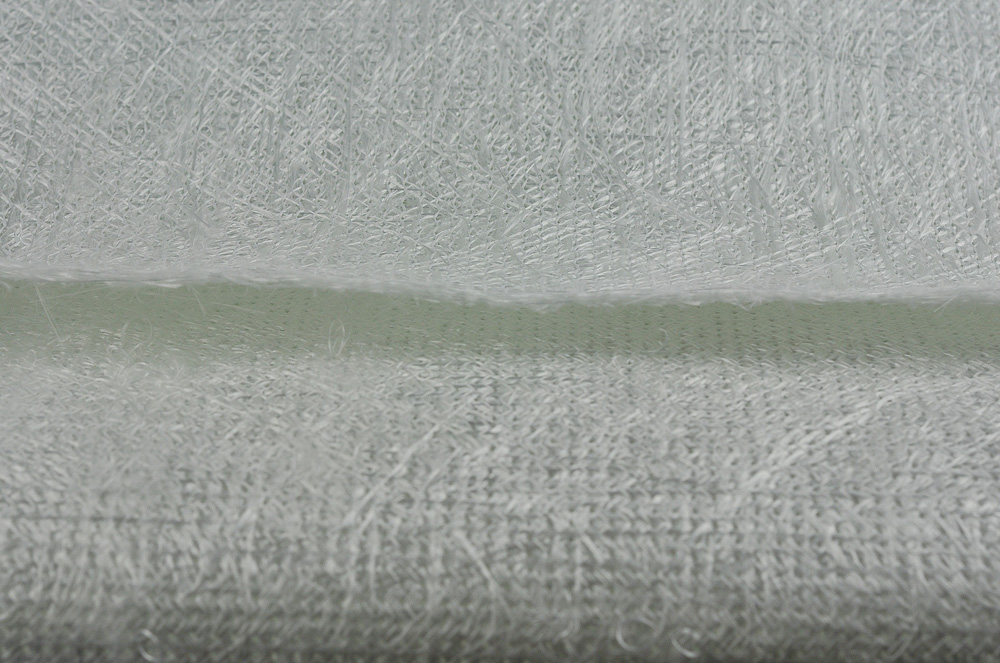

双短切夹芯毡

Chopped core mat

众杰玻璃纤维短切夹芯毡是由玻璃纤维短切原丝呈上下两层无序排列在PP、PET或者尼龙芯材上,以聚酯缝编线缝编而成的夹芯织物。适用于各种树脂增强系统,如聚氨酯、不饱和聚酯树脂,乙烯基树脂和环氧树脂等。广泛应用于RTM、真空导流等闭模成型工艺,如造船,风电机舱罩,汽车或火车零部件,平板型材及其他玻璃钢制品。

Chopped core mat is made of fiberglass chopped strands stitched by polyester yarn together with PP, PET or Nylon core materials like sandwich design. It is compatible with Polyester, Vinyl and Epoxy resin and widely used in boat building, wind energy, automotive, train parts, flat panels etc, suitable for RTM, vacuum infusion, hand lay up forming processes.

基本数据

General Data

规格型号 Code | 质量 Weight (g/m2) | 短切层/短切层 Chopped layer (g/m2) | 夹芯层PP Core layer (g/m2) | 含水率% Moisture content | 浸透速度 Wet speed (≤S) |

EMNM300/180/300 | 780 | 300/300 | 180 | ≤0.2 | ≤60 |

EMNM450/180/450 | 1080 | 450/450 | 180 | ≤0.2 | ≤60 |

EMNM600/180/600 | 1380 | 600/600 | 180 | ≤0.2 | ≤60 |

EMNM750/180/750 | 1680 | 750/750 | 180 | ≤0.2 | ≤60 |

EMNM300/250/300 | 850 | 300/300 | 250 | ≤0.2 | ≤60 |

EMNM450/250/450 | 1150 | 450/450 | 250 | ≤0.2 | ≤60 |

EMNM600/250/600 | 1450 | 600/600 | 250 | ≤0.2 | ≤60 |

EMNM750/250/750 | 1750 | 750/750 | 250 | ≤0.2 | ≤60 |

Remarks:

Roll width: Standard width in 1250mm, 1270mm, and other sizes depends on customer’s real needs, available in 200mm to 3200mm.

Packing: Fiberglass chopped core mat is usually rolled in a paper tube with inner diameter 76mm. The roll is warped with plastic film, then put into carton. Lay the rolls horizontally, and can be loaded on pallets and bulk in container.

Storage: The product should be stored in a cool, water-proof area. It is recommended that the room temperature and humidity be always maintained at 15℃ to 35℃ and 35% to 65% respectively. Please keep the product in its original packaging before being used, avoiding moisture absorption.

苏公网安备32041102001451号

苏公网安备32041102001451号

苏公网安备32041102001515号

苏公网安备32041102001515号